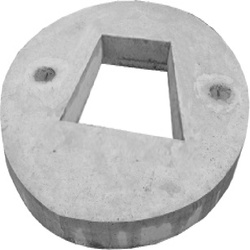

Ogee Joint Concrete Pipes

Used for land surface water drainage systems.

- The designer has more control over pipe strength than any other facet of the

- project.

- There is less reliance on quality installation by the installer.

- There is lower embedment material cost.

- There is less compaction required.

- It is easier to maintain grade and alignment.

- There are no excess deflection concerns.

- There is a lower life cycle cost of the project.

- There is a lower maintenance cost over the design life of the project.

- There is a reduced likelihood of failure.

- A lower risk for the specifier, designer and owner of the project, and reduced overall

- liability to the public after the project has been commissioned.

|

Application |

Product Code |

ID (mm) |

ED (mm) |

Effective Length(mm) |

Weight(kgs) |

Wall Thickness(mm) |

l1 (mm) |

l2 (mm)

|

| Used for land surface water drainage systems. |

1-15-220-0100-1000

|

100 |

150 |

1000 |

24 |

25 |

15 |

15 |

|

|

1-15-220-0150-1000

|

150 |

205 |

1000 |

35 |

28 |

20 |

20 |

|

|

1-15-220-0225-1000

|

225 |

285 |

1000 |

65 |

30 |

20 |

20 |

|

|

1-15-220-0300-1000

|

300 |

375 |

1000 |

87 |

38 |

25 |

25 |

|

|

1-15-220-0375-1000

|

375 |

455 |

1000

|

117 |

40 |

27 |

27 |

|

|

1-15-220-0450-1000

|

450 |

535 |

1000 |

148 |

43 |

30 |

30 |

|

|

1-15-220-0525-1000

|

525 |

625 |

1000 |

187 |

50 |

32 |

32 |

|

|

1-15-220-0600-1000

|

600 |

715 |

1000 |

261 |

58 |

37 |

37 |

|

|

1-15-220-0760-1000

|

760 |

890 |

1000 |

402 |

65 |

45 |

45 |

|

|

1-15-220-0915-1000

|

915 |

1055 |

1000 |

535 |

70 |

45 |

45 |

|

|

1-15-220-1070-1000

|

1070 |

1250 |

1000 |

600 |

70 |

45 |

45 |

|

|

1-15-220-1200-1000

|

1200 |

1350 |

1000 |

760 |

75 |

50 |

50 |

|

|

1-15-220-1350-1000

|

1350 |

1530 |

1000 |

870 |

90 |

75 |

75 |

|

|

1-15-220-1500-1000

|

1500 |

1700 |

1000 |

1207 |

100 |

75 |

75

|